Air bubble remover:

Quicktoron

- Quicktoron is a device to remove air bubbles from liquids.

- It’s based on the cyclone principle, and very efficiently eliminates all the fine air bubbles trapped and mixed inside the fluid.

- Quicktoron also helps to retain the filtration performance of filter elements. Most air bubbles have a larger sizes than solid contaminants. When these air bubbles go through the filter elements, they create bigger channels, allowing contaminants to pass through without being captured, and dropping filtration performance of the oil filters.

- Quicktoron devices are very compact, easy to install, and offer a very economical solution to remove air bubbles quickly and efficiently.

- Typically Quicktoron is used in combination with our OSCA-series.

Consequences of air bubbles in oil

- Creates excessive noise and vibration

- Increases friction and wear of moving parts

- Accelerated oxidation of the fluid

- Accelerated metal corrosion, lower cooler efficiency

- Causes measurement errors

Benefits of the air bubble remover

- Eliminates up to 95% of all air bubbles!

- Allows to use a small oil reservoir, very common in case of mobile equipment.

- Avoids pump cavitation and improves machine reliability and component life.

- Extends oil life.

- Improves oil filters efficiency.

- Improves coolers efficiency.

- Improves power transmission and saves on energy

Working principles

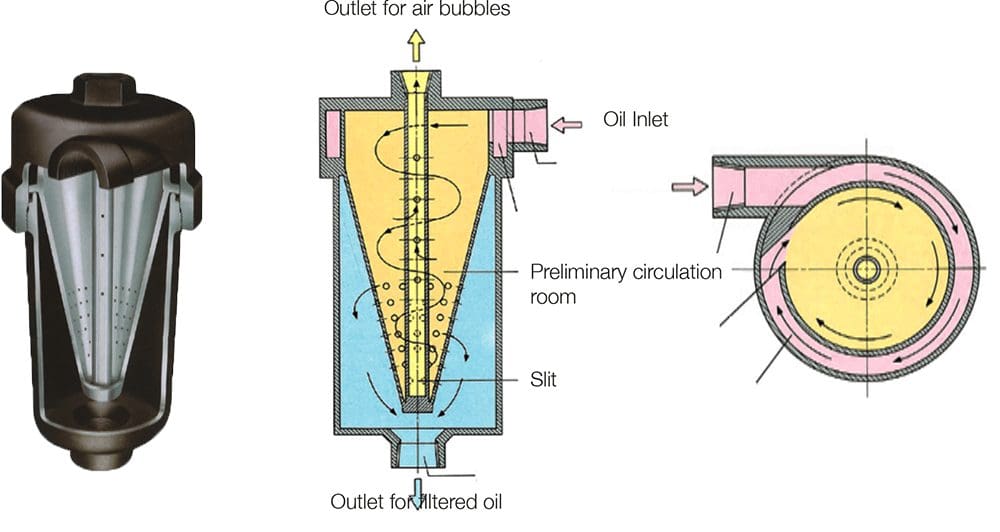

The Quicktorons are based on the cyclone principle.

The shape of a Quicktoron has been engineered to create a cyclone effect inside the housing. The oil will circle high speed and force the air bubbles to the center. From there, the air bubbles will be forced to the upper side and leave the Quicktoron via the upper outlet port.

For best results, we recommend adjusting the flow rate at the Outlet for air bubbles to roughly 5 to 7% of the primary pump delivery. The ratio of air and fluid that will flow through the air bubble outlet line varies depending on how much air is mixed in the fluid. The air bubble outlet line must also be directed to the oil tank. But it is best to locate this outlet far from the oil suction area inside the machines and against a side panel into the air (as close as possible above the liquid level).

The main oil flow will exit the housing through the port at the bottom and must be directed to the oil tank, avoiding counterpressure.

Contact Us for Comprehensive Solutions

Experience our top-notch filtration and oil cleaning solutions designed to meet your specific needs. Our dedicated team is ready to assist you with any inquiries, technical support, or scheduling consultations.